Supplier Prequalification and Monitoring

Pre-qualification for Construction Groups

Access the largest Community of Pre-qualified Suppliers ready to work with you, at no cost to you.

Take advantage of the power of CAE and Marketplace integration to enjoy more information, better monitoring, and easy trading.

The most efficient way to pre-qualify the supply chain for companies belonging to Construction Groups.

Ensure that your procurement processes are sustainable, legal and reliable.

There are good reasons to automate the pre-qualification of your suppliers:

- Complex and evolving regulatory compliance.

- Saving time for collecting, auditing and monitoring information and evidence.

- Risk reduction, transparency and procurement optimisation.

And all the more reason to do so in the Construction Community:

- Immediate implementation: subcontractors ready to pre-qualify now.

- Use the information from the CAE to find out even more.

- Trade with your chain through the integrated Marketplace .

Reliable and resilient supply chains for your construction sites, services, concessions, energy and infrastructure.

Benefit from the network intelligence of the largest Community of Construction Groups and our specialisation in the sector.

Essential compliance, ready right out of the box, and the rest, as flexible as you need it to be.

Easily control and extend your supply chain with reliable and creditworthy suppliers effortlessly.

- Immediately fulfil your due diligence obligations with our standard pre-qualification: yours and new.

- Add your own questionnaires with complete flexibility.

- Free yourself from collecting, auditing and monitoring information and evidence from your suppliers.

Improve your supply chain performance with data-driven decisions

Segment your supply chain by any criteria and consult interactive dashboards to decide in real time.

- Segment by activity, scope, project, work, level of compliance or any ad hoc criteria and make it public or private.

- Analyse each segment in powerful PowerBI dashboards and drill down to the highest level.

- Notifies any segment of changes in compliance status, new requirements, or anything else.

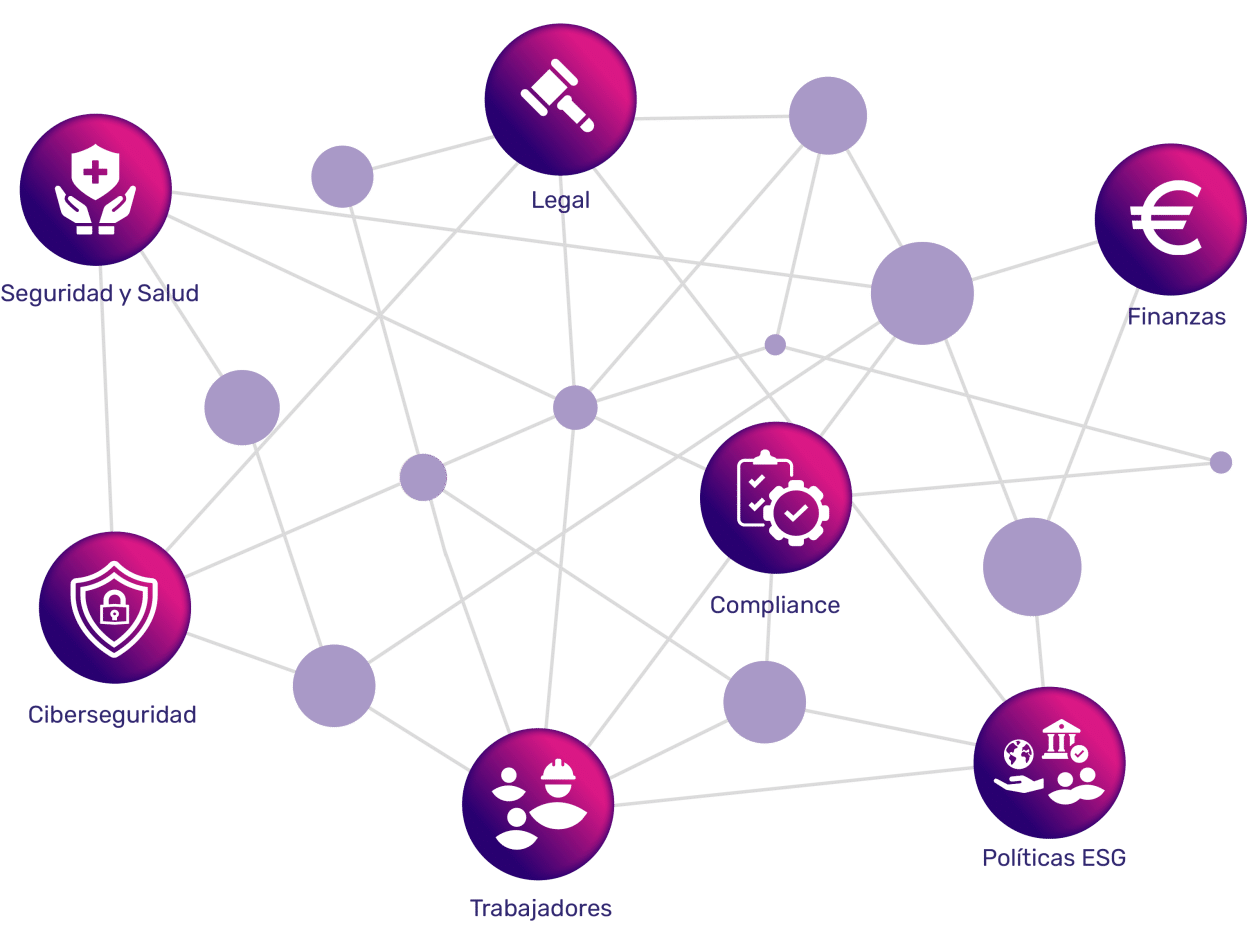

Synergistically connected to other processes in your supply chain

Share all supplier information generated through your company's various processes and enable everyone to make better decisions and operate better.

- Connected to the CAE

- It provides you with more information on labour law and HSE.

- It informs you of previous work carried out

- Include subcontractors automatically in your subcontracting chain.

- It can make payments conditional on compliance.

- Connected to the Marketplace, it enables one-click purchasing and research to be triggered to the right segments of the chain.

All of these construction groups operate here

Exchanging information with over

+100k suppliers

to optimize your compliance, operations and business relationships.

FAQ Supplier pre-qualification

In Spain, a construction company may be obliged to implement a supplier pre-qualification system for a number of legal reasons arising from current regulations on procurement, occupational risk prevention, social responsibility and financial control.

1. Compliance with the Public Sector Contracts Act ( LCSP)

If the construction company works on public contracts, it must comply with Law 9/2017 on Public Sector Contracts (LCSP), which requires capacity, solvency and qualification criteria for subcontractors and suppliers. A pre-qualification system makes it possible to ensure that:

– Suppliers meet the requirements of economic and technical solvency (Art. 65-74).

– The absence of prohibitions to contract is verified (art. 71).

– Sustainability, quality and safety criteria are evaluated (art. 145).

2. Occupational Risk Prevention (ORP)

Royal Decree 171/2004 establishes the coordination of business activities in terms of occupational risk prevention. The construction company is legally obliged to ensure that suppliers:

– They are adequately trained and equipped in occupational safety.

– They comply with OHS regulations before entering a construction site.

– They have security protocols in place as required by law.

A pre-qualification system makes it possible to filter out suppliers who do not comply with these requirements and to avoid sanctions or industrial accidents that could result in liability for the contracting company.

3. Joint and Several Liability in Labour and Social Security Matters

– According to Article 42 of the Workers’ Statute, the main company is jointly and severally liable for the salary and Social Security obligations of contractors and subcontractors. Pre-qualification helps to:

– Verify that suppliers are up to date with their Social Security payments.

– Avoid contracting with companies that may generate risks of non-payment or labour lawsuits.

4. Control of Money Laundering and Tax Fraud

Royal Decree 304/2014, which implements Law 10/2010 on the Prevention of Money Laundering, obliges companies to control their suppliers to avoid financial and legal risks. Pre-qualification allows:

– Verify that suppliers are not involved in illegal activities.

– Ensure that they comply with tax and accounting regulations (be up to date with the tax authorities).

5. Construction Subcontracting Regulations (Law 32/2006)

Law 32/2006 and its regulation (RD 1109/2007) regulate subcontracting in the construction sector. It requires subcontracting companies to comply with certain requirements:

– Registration in the Register of Accredited Companies (REA).

– Justification of technical solvency and adequate means.

– Compliance with limits in the subcontracting chain.

A pre-qualification system allows to check that all suppliers meet these requirements before contracting them.

6. Sustainability and Corporate Social Responsibility (CSR)

Since Law 11/2018 on non-financial reporting and diversity, many companies must report their social and environmental impact. The construction company may be legally responsible for:

– Environmental impacts of your supply chain.

– Forced or exploitative labour in its supplier network.

– Compliance with sustainability criteria required in public projects.

A pre-qualification system helps to meet these standards and avoid reputational and legal risks.

7. Data Protection (RGPD and LOPDGDD)

If the construction company works with suppliers that handle personal data, it is obliged to ensure that they comply with the General Data Protection Regulation (RGPD) and Organic Law 3/2018 (LOPDGDD). Pre-qualification allows:

– Assess whether suppliers have adequate data protection measures in place.

– Avoiding sanctions for non-compliance in the processing of personal information.

Conclusion

The implementation of a pre-qualification system is not only good business practice, but also meets legal obligations in terms of public procurement, occupational safety, taxation, sustainability and data protection. It also protects the company from financial, legal and reputational risks.

1. Corporate Sustainability Due Diligence Directive ( CSDDD)

(Corporate Sustainability Due Diligence Directive – CSDDD)

Approved in February 2024 by the European Parliament, pending transposition in Spain.

It is important to note that, although full transposition of the directive must be completed by July 2026, companies must start preparing to comply with these new obligations by implementing measures to ensure respect for human rights and the environment in all their operations and supply chains.

Relevant Obligations for Construction

– It requires large companies to monitor and manage social and environmental risks throughout their supply chain.

– Construction companies must assess and mitigate human rights, labour and environmental risks of their suppliers.

– Measures against forced labour, deforestation, pollution and corruption are included in the hiring of subcontractors.

– Financial penalties and restrictions on public contracts can be imposed on companies that do not comply.

Impact on Supplier Prequalification

Construction companies will need a supplier evaluation system based on ESG (environmental, social and governance) criteria.

It will be mandatory to implement audit and control protocols to ensure that suppliers comply with regulations.

Companies that do not adequately control their supply chain could face civil liability and debarment from public contracts.

2. Critical Raw Materials Regulations (CRMA)

(Critical Raw Materials Act – CRMA)

In the process of approval by the EU, it will affect sectors that depend on strategic materials.

Relevant Obligations for Construction

Requires companies using critical materials (steel, copper, cement, etc.) to verify the traceability of their origin.

Introduces controls on sustainable sourcing and the reduction of dependence on third countries.

Construction companies must demonstrate that their suppliers meet environmental and social standards in the extraction and production of materials.

Impact on Supplier Prequalification

Construction companies will have to select suppliers that meet sustainability criteria for materials.

There will be certification and auditing requirements to ensure that materials are responsibly sourced.

3. EU Deforestation Regulation (EUDR)

Status: Applicable from December 2024.

Relevant Obligations for Construction

Requires companies to check that their suppliers do not contribute to illegal deforestation.

Applies to timber, rubber and other materials used in construction.

Proof of legal and sustainable origin of materials must be provided before marketing them in the EU.

📌 Impact on Supplier Prequalification

Construction companies should require sustainable origin certifications for timber and rubber materials.

Due diligence checks should be included in supplier selection processes.

4. Corporate Sustainability Reporting Directive (CSRD)

(Corporate Sustainability Reporting Directive – CSRD)

Status: Applicable in Spain from 2024, affects large companies and soon SMEs.

Relevant Obligations for Construction

Obliges companies to report on the environmental and social impact of their supply chain.

Requires transparency in the consumption of natural resources, CO₂ emissions and labour conditions of suppliers.

Construction companies must report on actions to mitigate impacts in the value chain.

Impact on Supplier Pre-qualification

Suppliers will be required to provide sustainability data and comply with international standards (GRI, ESRS).

A system for evaluating and ranking suppliers according to their ESG impact will be key.

5. European Construction Products Regulation (CPR) – Revision

Status: Under revision, new version expected to enter into force in 2025.

Relevant Obligations for Construction

Increases requirements on sustainability, recyclability and energy efficiency of building materials.

Requires manufacturers and distributors to declare the environmental impact of their products.

Stricter standards will be set for material quality and safety.

Impact on Supplier Prequalification

The construction company should only work with suppliers that certify compliance with the new standards.

Energy efficiency and carbon footprint reduction criteria will have to be included in the prequalification.

Conclusion: The Need for a Supplier Pre-qualification System

Given the increasing regulatory pressure in Europe, the implementation of a supplier pre-qualification system is essential to:

– Avoid sanctions for non-compliance.

– Ensure traceability of materials and their sustainable origin.

– Mitigate social and environmental responsibility risks.

– Ensure access to public tenders that require ESG compliance and due diligence.

– Reduce the risk of litigation and sanctions in the areas of human rights and the environment.

This system should include audits, certifications, contractual clauses and supplier evaluation tools to ensure that they comply with European and Spanish requirements.

If you have reached this question, it is very likely that you belong to one of the thousands of companies belonging to Construction Groups in Spain: building, concessions, services, energy, industry, etc.

You will know then that on our platform the CAE is carried out by the subcontractors of all these main contractors, and they do it in a Construction Community, with a model in which the subcontractors contribute a sustainable fee for their documentation to be reviewed. The main contractors in return, finance their specific and particular conditions, in order to make the Community model fair.

All invest to mitigate risk.

The pre-qualification model works in the same way.

– There is an essential pre-qualification included in the fee for all our CAE clients that leaves them ready for you to pre-qualify your supply chain.

– If your company does the CAE with us, all your subcontractors are on the platform and those that are active can pre-qualify with you and the whole community, and we have included them by default in your initial supply chain, which you can modify as you wish.

– If you have your own requirements, about questionnaires, evidence, etc., our platform, especially oriented to the construction group sector, is as flexible as you need it to be. This is when we will talk about budgets, but you will have been able to deduct all the essential pre-qualification from your investment.

– If you want to extend your supply chain, you can do so very easily as tens of thousands of subcontractors operate on our platform every day.

– If you want to interact directly with your supply chain, you can do so naturally through a Marketplace that we make available to buyers and sellers free of charge. Purchases, surveys, expressions of interest, invitations to join the supply chain: all of this can be done in an integrated way.